POLYMERS

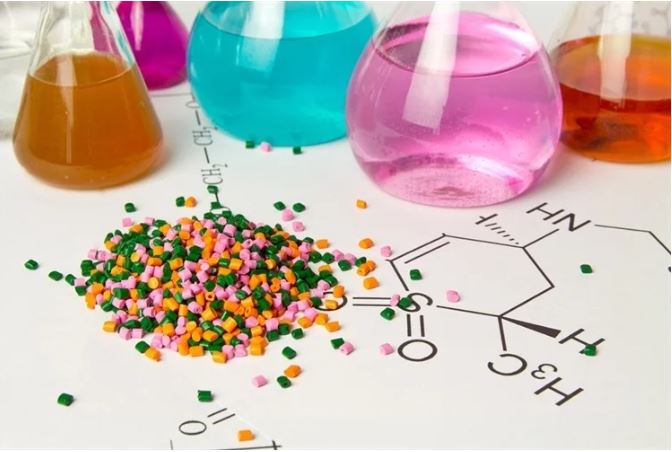

We Are Providing Wide Range Of Plastic Resins

We have the broadest portfolio and the information you need – right at your fingertips.

Polymers Products We Serve

Are you looking for a resin combines high transparency, impact resistance, and sparkling clarity and? Then consider lines est copolymers for your next exciting application. It can be injection molded, extruded, or thermoformed by itself or as a blend to improve the impact of polystyrene.

High-Density Polyethylene (HDPE) is a versatile polymer known for its robustness and durability. This thermoplastic is widely used in various industries for its exceptional strength-to-density ratio and resistance to different chemicals and moisture. HDPE finds applications in manufacturing plastic bottles, pipes, packaging materials, and geomembranes due to its excellent stiffness, toughness, and ability to withstand harsh environmental conditions. Its versatility and recyclability make it a popular choice for a wide range of products, contributing to its significance in modern industries.

Low-Density Polyethylene (LDPE) is a flexible and lightweight thermoplastic known for its versatility and ease of processing. This type of polymer is commonly used in various applications due to its excellent resistance to moisture, chemicals, and impact. LDPE is often utilized in packaging materials, including plastic bags, shrink wraps, and containers, owing to its flexibility and transparency. Its malleability makes it suitable for manufacturing flexible products like squeeze bottles, tubing, and coatings. LDPE's widespread use stems from its ability to provide reliable protection.

Polyethylene (PE) represents a widely used thermoplastic polymer renowned for its versatility and applicability across numerous industries. Its exceptional durability, chemical resistance, and ease of fabrication make it an invaluable material in various applications. Available in different forms such as High-Density Polyethylene (HDPE) and Low-Density Polyethylene (LDPE), PE finds extensive use in manufacturing plastic bottles, packaging materials, pipes, films, and containers. Its adaptability and capability to endure diverse environmental conditions contribute to its widespread use, serving as a cornerstone material for countless everyday products due to its reliability, strength, and cost-effectiveness.

Polyethylene Terephthalate (PET) is a widely used thermoplastic polymer celebrated for its exceptional clarity, strength, and recyclability. Renowned for its transparent appearance akin to glass, PET is commonly utilized in the production of beverage bottles, food packaging, and fibers for clothing. Its robustness and ability to withstand high levels of impact and temperature variations make it an ideal choice for various applications. PET's eco-friendly nature, as it is easily recyclable, has led to its popularity as a sustainable packaging option across industries. Its versatility, combined with its ability to be repurposed, positions PET as a material of choice for manufacturers seeking durable.

Linear Low-Density Polyethylene (LLDPE) is a highly versatile thermoplastic renowned for its exceptional flexibility and toughness. It is characterized by its unique molecular structure, composed of linear chains with short branches, offering improved puncture resistance and enhanced flexibility compared to other polyethylene types. LLDPE's remarkable strength and resistance to various chemicals make it a preferred choice in packaging applications, including stretch wraps, flexible films, and liners for containers. Its ability to conform to irregular shapes while maintaining strength and durability makes LLDPE an ideal material for protecting goods during transit and storage. Widely appreciated for its cost-effectiveness and reliability, LLDPE continues to be a crucial material across industries requiring flexible and robust packaging solutions.

Polypropylene (PP) is a versatile thermoplastic polymer known for its exceptional strength, heat resistance, and durability. Renowned for its high melting point and robustness, PP finds extensive use in a wide array of applications across various industries. Its versatility allows it to be used in manufacturing packaging materials, including food containers, bottle caps, and flexible packaging films, owing to its excellent resistance to moisture, chemicals, and fatigue. Additionally, PP's ability to withstand high temperatures without deformation makes it suitable for use in microwave-safe containers and dishwasher-safe products. Its lightweight nature, combined with its toughness and recyclability, positions PP as a popular choice for manufacturers seeking reliable, cost-effective, and sustainable materials for diverse applications.

Powerd by choudharyglobal.com